Valve ea Serurubele ea Fektheri e Rekisoang ka ho Otloloha ea Fektheri ea Boholo bo Tloaelehileng Ductile Cast Iron Wafer Connection API Butterfly Valve bakeng sa Khase ea Oli ea Metsi

Senotlolo sa katleho ea rona ke "Thepa e Ntle ea Boleng bo Holimo, Litšenyehelo tse Loketseng le Tšebeletso e Sebetsang" bakeng sa Fektheri e Rekisoang ka ho Chesa Ductile Cast Iron Lug Type WaferValve ea SerurubeleAPI Butterfly Valve bakeng sa Khase ea Oli ea Metsi, Rea u amohela hore u kopanele le rona tseleng ena ea ho etsa khoebo e ruileng le e hlahisang litholoana hammoho.

Senotlolo sa katleho ea rona ke "Thepa e Ntle ea Boleng bo Holimo, Litšenyehelo tse Loketseng le Tšebeletso e Sebetsang Hantle" bakeng saValve ea Serurubele ea Chaena le Valve ea Serurubele ea Wafer, Kamehla re khomarela molao-motheo oa k'hamphani oa "botšepehi, botsebi, bo sebetsang le boqapi", le mesebetsi ea: a re bakhanni bohle ba natefeloe ke ho khanna ha bona bosiu, a re basebetsi ba rona ba hlokomele bohlokoa ba bophelo ba bona, 'me ba be matla le ho sebeletsa batho ba bangata. Re ikemiselitse ho ba mohlophisi oa 'maraka oa rona oa lihlahisoa le mofani oa litšebeletso oa sebaka se le seng oa 'maraka oa rona oa lihlahisoa.

Tlhaloso:

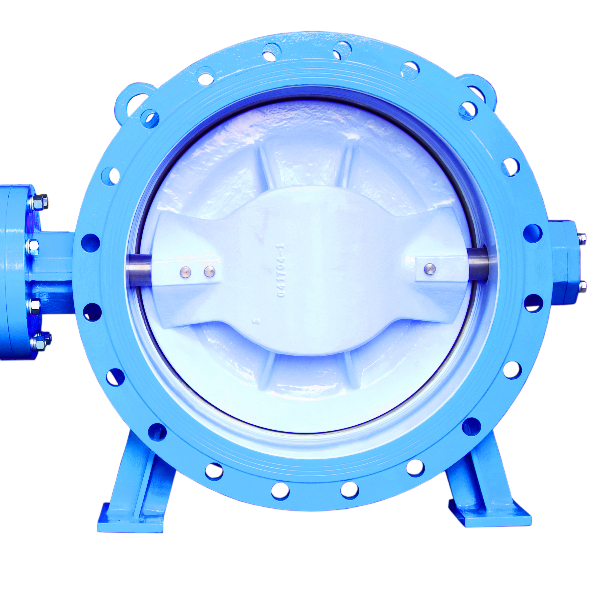

Khokahano ea flange ea YD Series Wafer butterfly valve ke ea maemo a lefats'e, 'me thepa ea mohele ke aluminium; E ka sebelisoa e le sesebelisoa sa ho khaola kapa ho laola phallo liphaepheng tse fapaneng tsa mahareng. Ka ho khetha lisebelisoa tse fapaneng tsa disc le setifikeiti sa tiiso, hammoho le khokahano e se nang phini pakeng tsa disc le kutu, valve e ka sebelisoa maemong a mabe le ho feta, joalo ka vacuum ea desulphurization, desalination ea metsi a leoatle.

E entsoe ka ho nahana ka ho tšoarella, wafer ea ronali-valve tsa serurubele tse tebilengli hahiloe ka thepa ea boleng bo holimo ho mamella maemo a thata ka ho fetisisa a indasteri. Kaho ea eona e tiileng e netefatsa ts'ebetso e tšoarellang nako e telele le litlhoko tse fokolang tsa tlhokomelo, e u bolokelang nako le chelete qetellong.

Valve ena e na le moralo o monyane le o bobebe, e leng se etsang hore ho be bonolo haholo ho e kenya le ho e sebelisa. Sebopeho sa eona sa setaele sa wafer se lumella ho kenngoa kapele le habonolo lipakeng tsa li-flange, e leng se etsang hore e be sebaka se setle bakeng sa libaka tse thata le lits'ebetso tse hlokomelang boima. Ka lebaka la litlhoko tse tlase tsa torque, basebelisi ba ka fetola boemo ba valve habonolo ho laola phallo ka nepo ntle le ho hatella lisebelisoa.

Ntlha e ka sehloohong ea li-valve tsa rona tsa lirurubele tsa wafer ke bokhoni ba tsona bo botle ba ho laola phallo. Moralo oa eona o ikhethang oa disc o etsa phallo ea laminar, o fokotsa ho theoha ha khatello le ho eketsa katleho ea ts'ebetso. Sena ha se ntlafatse ts'ebetso ea sistimi ea hau feela empa hape se fokotsa tšebeliso ea matla, e leng se fellang ka ho boloka litšenyehelo tse kholo bakeng sa ts'ebetso ea hau.

Polokeho ke ea bohlokoa haholo tikolohong efe kapa efe ea indasteri 'me li-valve tsa rona tsa lirurubele tsa wafer li ka khotsofatsa litlhoko tsa hau. E na le mokhoa oa ho notlela ka polokeho o thibelang ts'ebetso ea li-valve ka phoso kapa e sa lumelloang, ho netefatsa hore ts'ebetso ea hau e tsamaea hantle ntle le tšitiso efe kapa efe. Ho feta moo, thepa ea eona ea ho koala ka thata e fokotsa ho lutla, e eketsa ts'epo ea sistimi ka kakaretso le ho fokotsa kotsi ea nako ea ho se sebetse kapa tšilafalo ea sehlahisoa.

Ho feto-fetoha ha maemo ke tšobotsi e 'ngoe e ikhethang ea li-valve tsa rona tsa lirurubele tse mamellang wafer. Li loketse mefuta e mengata ea lits'ebetso ho kenyeletsoa le kalafo ea metsi, litsamaiso tsa HVAC, ts'ebetso ea lik'hemik'hale, oli le khase, le tse ling, li-valve li fana ka litharollo tsa taolo tse tšepahalang le tse sebetsang hantle bakeng sa liindasteri tse fapaneng.

Waferli-valve tsa serurubele tse lutseng ka rabarafana ka litharollo tse tšepahalang le tse theko e tlaase tsa taolo ea phallo bakeng sa lits'ebetso tse fapaneng. Ka kaho ea eona e tšoarellang, ho e kenya habonolo, bokhoni bo phahameng ba taolo ea phallo le likarolo tse matla tsa polokeho, valve ena ntle ho pelaelo e tla feta litebello tsa hau 'me e bapale karolo ea bohlokoa ho ntlafatseng katleho ea ts'ebetso ea hau. Latsoa ts'ebetso e sa bapisoang ea li-valve tsa rona tsa lirurubele tsa wafer 'me u ise lits'ebetso tsa hau tsa indasteri maemong a macha.

Tšobotsi:

1. E nyane ka boholo le boima bo bobebe mme e bonolo ho e hlokomela. E ka kenngwa kae kapa kae moo ho hlokahalang.

2. Sebopeho se bonolo, se kopane, ts'ebetso e potlakileng ea ho tima likhato tse 90

3. Disiki e na le bere ea mahlakore a mabeli, tiiso e phethahetseng, ntle le ho dutla tlas'a teko ea khatello.

4. Mothapo o phallang o shebile moleng o otlolohileng. Tshebetso e ntle haholo ya taolo.

5. Mefuta e fapaneng ea thepa, e sebetsang mecheng e fapaneng ea litaba.

6. Ho hanyetsa ho hlatswa le borashe ka matla, mme ho ka lekana le boemo bo bobe ba ho sebetsa.

7. Sebopeho sa poleiti e bohareng, torque e nyane ea ho bula le ho koala.

8. Bophelo bo bolelele ba tšebeletso. Ho mamella teko ea mesebetsi ea ho bula le ho koala ea likete tse leshome.

9. E ka sebelisoa ho khaola le ho laola mecha ea phatlalatso.

Tšebeliso e tloaelehileng:

1. Morero oa mesebetsi ea metsi le mehloli ea metsi

2. Tšireletso ea Tikoloho

3. Meaho ea Sechaba

4. Motlakase le Litšebeletso tsa Sechaba

5. Indasteri ea kaho

6. Petroleum/ Lik'hemik'hale

7. Tšepe. Tšepe

8. Indasteri ea ho etsa pampiri

9. Lijo/Lino jj.

Tekanyo:

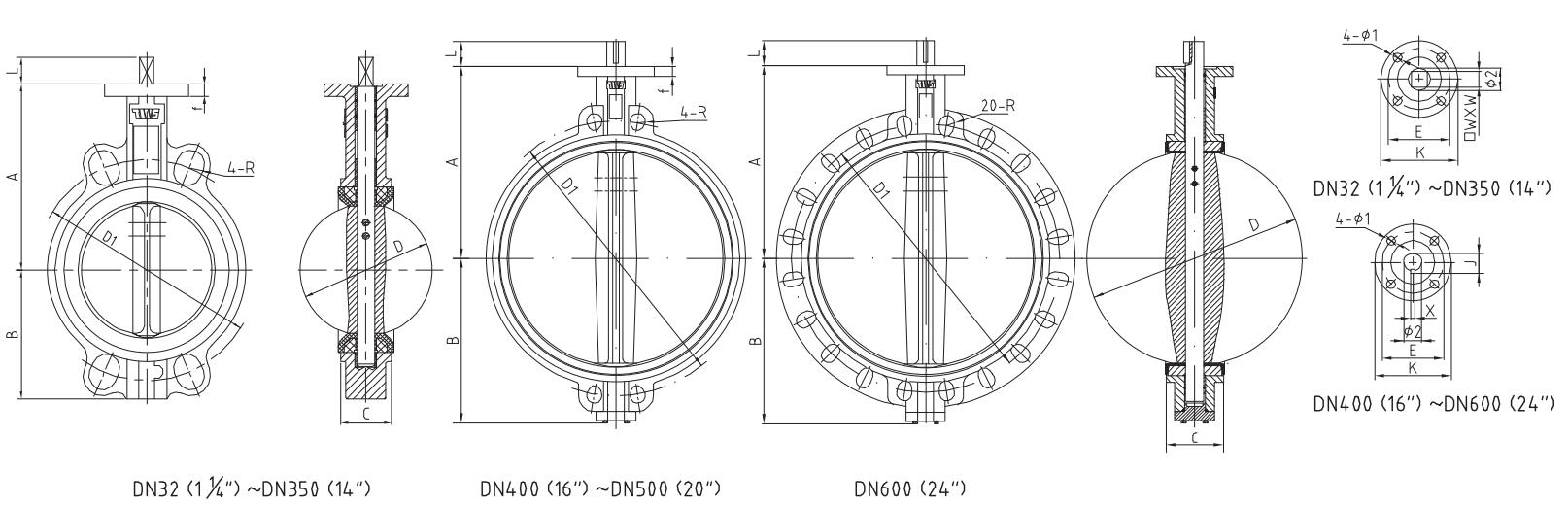

| Boholo | A | B | C | D | L | D1 | D2 | Φ1 | ΦK | E | R1 (PN10) | R2 (PN16) | Φ2 | f | j | x | □w*w | Boima (kg) | |

| mm | intshi | ||||||||||||||||||

| 32 | 1 1/4 | 125 | 73 | 33 | 36 | 28 | 100 | 100 | 7 | 65 | 50 | R9.5 | R9.5 | 12.6 | 12 | – | – | 9*9 | 1.6 |

| 40 | 1.5 | 125 | 73 | 33 | 43 | 28 | 110 | 110 | 7 | 65 | 50 | R9.5 | R9.5 | 12.6 | 12 | – | – | 9*9 | 1.8 |

| 50 | 2 | 125 | 73 | 43 | 53 | 28 | 125 | 125 | 7 | 65 | 50 | R9.5 | R9.5 | 12.6 | 12 | – | – | 9*9 | 2.3 |

| 65 | 2.5 | 136 | 82 | 46 | 64 | 28 | 145 | 145 | 7 | 65 | 50 | R9.5 | R9.5 | 12.6 | 12 | – | – | 9*9 | 3 |

| 80 | 3 | 142 | 91 | 46 | 79 | 28 | 160 | 160 | 7 | 65 | 50 | R9.5 | R9.5 | 12.6 | 12 | – | – | 9*9 | 3.7 |

| 100 | 4 | 163 | 107 | 52 | 104 | 28 | 180 | 180 | 10 | 90 | 70 | R9.5 | R9.5 | 15.8 | 12 | – | – | 11*11 | 5.2 |

| 125 | 5 | 176 | 127 | 56 | 123 | 28 | 210 | 210 | 10 | 90 | 70 | R9.5 | R9.5 | 18.9 | 12 | – | – | 14*14 | 6.8 |

| 150 | 6 | 197 | 143 | 56 | 155 | 28 | 240 | 240 | 10 | 90 | 70 | R11.5 | R11.5 | 18.9 | 12 | – | – | 14*14 | 8.2 |

| 200 | 8 | 230 | 170 | 60 | 202 | 38 | 295 | 295 | 12 | 125 | 102 | R11.5 | R11.5 | 22.1 | 15 | – | – | 17*17 | 14 |

| 250 | 10 | 260 | 204 | 68 | 250 | 38 | 350 | 355 | 12 | 125 | 102 | R11.5 | R14 | 28.5 | 15 | – | – | 22*22 | 23 |

| 300 | 12 | 292 | 240 | 78 | 302 | 38 | 400 | 410 | 12 | 125 | 102 | R11.5 | R14 | 31.6 | 20 | – | – | 22*22 | 32 |

| 350 | 14 | 336 | 267 | 78 | 333 | 45 | 460 | 470 | 14 | 150 | 125 | R11.5 | R14 | 31.6 | 20 | 34.6 | 8 | – | 43 |

| 400 | 16 | 368 | 325 | 102 | 390 | 51/60 | 515 | 525 | 18 | 175 | 140 | R14 | R15.5 | 33.2 | 22 | 36.2 | 10 | – | 57 |

| 450 | 18 | 400 | 356 | 114 | 441 | 51/60 | 565 | 585 | 18 | 175 | 140 | R14 | R14 | 38 | 22 | 41 | 10 | – | 78 |

| 500 | 20 | 438 | 395 | 127 | 492 | 57/75 | 620 | 650 | 18 | 175 | 140 | R14 | R14 | 41.1 | 22 | 44.1 | 10 | – | 105 |

| 600 | 24 | 562 | 475 | 154 | 593 | 70/75 | 725 | 770 | 22 | 210 | 165 | R15.5 | R15.5 | 50.6 | 22 | 54.6 | 16 | – | 192 |

Senotlolo sa katleho ea rona ke "Thepa e Ntle ea Boleng bo Holimo, Litšenyehelo tse Loketseng le Tšebeletso e Sebetsang" bakeng sa thekiso e chesang ea fektheri ea Ductile Cast Iron Lug Type Wafer Butterfly Valve API Butterfly Valve bakeng sa Metsi Oli ea Khase, Rea u amohela hore u ikopanye le rona tseleng ena ea ho etsa khoebo e ruileng le e hlahisang litholoana hammoho.

Fektheri e rekisoang ka ho chesaValve ea Serurubele ea Chaena le Valve ea Serurubele ea Wafer, Kamehla re khomarela molao-motheo oa k'hamphani oa "botšepehi, botsebi, bo sebetsang le boqapi", le mesebetsi ea: a re bakhanni bohle ba natefeloe ke ho khanna ha bona bosiu, a re basebetsi ba rona ba hlokomele bohlokoa ba bophelo ba bona, 'me ba be matla le ho sebeletsa batho ba bangata. Re ikemiselitse ho ba mohlophisi oa 'maraka oa rona oa lihlahisoa le mofani oa litšebeletso oa sebaka se le seng oa 'maraka oa rona oa lihlahisoa.