Valve ea Serurubele ea Theko e Ntle ea Boleng bo Holimo ea Ductile Iron Rubber Tiiso ea Serurubele e nang le Khokahano ea Lug

Kgwebo ya rona e ikemiseditse ho sebetsa ka botshepehi, ho sebeletsa bareki bohle ba rona, le ho sebetsa theknolojing e ntjha le mochining o motjha ka ho tswela pele bakeng sa Ditheko tsa Theko e Ntle tsa ho lwantsha mollo ka ductile stem iron stem lug butterfly valve e nang le kgokelo ya Wafer, Boleng bo botle, ditshebeletso tse nakong le theko e matla, kaofela di re hapile botumo bo botle tshimong ya xxx ho sa tsotelehe tlholisano e matla ya matjhaba.

Kgwebo ya rona e ikemiseditse ho sebetsa ka botshepehi, ho sebeletsa bareki bohle ba rona, le ho sebetsa theknolojing e ntjha le mochining o motjha ka ho tswela pele bakeng saLi-valve tsa Chaena le Li-valve tsa Serurubele, Ka lihlahisoa tse ngata tsa Chaena lefatšeng ka bophara, khoebo ea rona ea machabeng e ntse e hola ka potlako 'me matšoao a moruo a eketseha haholo selemo le selemo. Re na le kholiseho e lekaneng ea ho u fa lihlahisoa le tšebeletso e betere, hobane re matla le ho feta, re litsebi ebile re na le boiphihlelo malapeng le machabeng.

Tlhaloso:

Valve ea serurubele ea mofuta oa MD Series Lug e lumella liphaephe tse theohelang le lisebelisoa ho lokisa inthaneteng, 'me e ka kenngoa lipheletsong tsa liphaephe e le valve ea mosi.

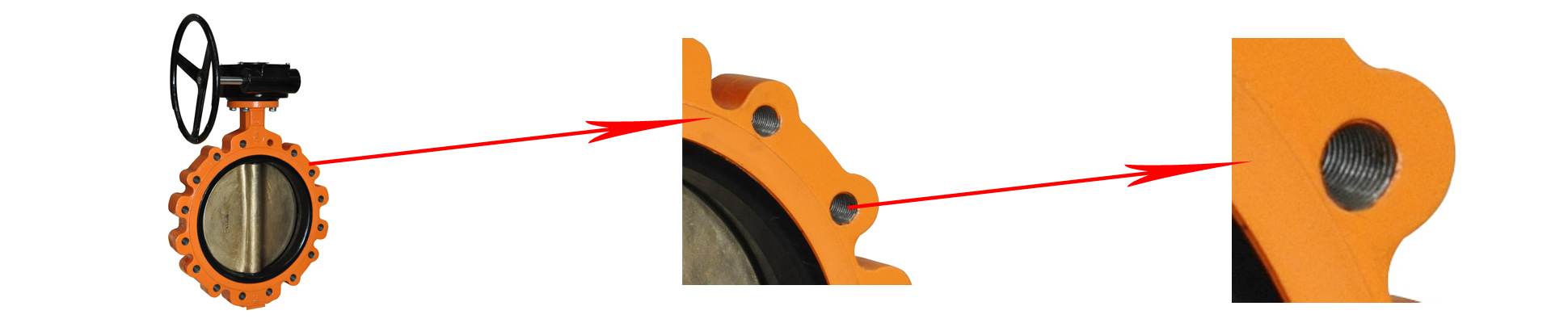

Litšobotsi tsa ho hokahanya 'mele o tlamiloeng li lumella ho kenngoa habonolo lipakeng tsa li-flange tsa liphaephe. Ho kenya ha 'nete ho boloka litšenyehelo, ho ka kenngoa pheletsong ea phaephe.

Mokotlavalavu ea serurubele e lutseng ka rabaraLi entsoe ka mokhoa oa ho fana ka ts'ebetso e ntle le ho tšoarella. E na le setulo sa rabara se tiisang ho koaloa ho tiileng le ho thibela ho lutla leha e le hofe nakong ea ts'ebetso. Setulo sa rabara se boetse se sebetsa e le mosamo, se fokotsa khohlano le ho fana ka taolo e boreleli le e nepahetseng ea phallo ea mokelikeli. Sena se etsa hore valve e be e loketseng bakeng sa lits'ebetso tsa ho bula/ho tima le ho thiba.

E 'ngoe ea litšobotsi tse ikhethang tsa li-valve tsa serurubele tsa mofuta oa lug ke ho tenyetseha ha tsona. 'Mele oa valve o etselitsoe ho mamella khatello le mocheso o phahameng, e leng se etsang hore o lokele ho sebelisoa libakeng tse thata. Paterone ea li-lug ea valve e ntlafatsa botsitso ba eona ha li-lug li fana ka tšehetso e eketsehileng ho valve, e e thibelang ho sisinyeha kapa ho petsoha tlas'a maemo a feteletseng.

Ntle le kaho ea bona e thata,valve ea serurubele ea lugLi boetse li bonolo ho li sebelisa. E etselitsoe ho kenya le ho hlokomela habonolo, e leng se lumellang ho fihlella ka potlako le habonolo kahare ho valve. Moralo oa lug o boetse o nolofalletsa ts'ebetso e sebetsang hantle, e lumellang valve ho sebetsa hantle.

Li-valve tsa rona tsa serurubele tsa setaele sa lug li fumaneha ka boholo le thepa e fapaneng ho fihlela litlhoko tse fapaneng tsa bareki ba rona. Hore na o hloka valve bakeng sa kalafo ea metsi, ts'ebetso ea lik'hemik'hale, tlhahiso ea motlakase kapa indasteri efe kapa efe, valve ena ke khetho e feto-fetohang ho fihlela litlhoko tsa hau tse ikhethileng.

Tšobotsi:

1. E nyane ka boholo le boima bo bobebe mme e bonolo ho e hlokomela. E ka kenngwa kae kapa kae moo ho hlokahalang.

2. Sebopeho se bonolo, se kopane, ts'ebetso e potlakileng ea ho tima likhato tse 90

3. Disiki e na le bere ea mahlakore a mabeli, tiiso e phethahetseng, ntle le ho dutla tlas'a teko ea khatello.

4. Mothapo o phallang o shebile moleng o otlolohileng. Tshebetso e ntle haholo ya taolo.

5. Mefuta e fapaneng ea thepa, e sebetsang mecheng e fapaneng ea litaba.

6. Ho hanyetsa ho hlatswa le borashe ka matla, mme ho ka lekana le boemo bo bobe ba ho sebetsa.

7. Sebopeho sa poleiti e bohareng, torque e nyane ea ho bula le ho koala.

8. Bophelo bo bolelele ba tšebeletso. Ho mamella teko ea mesebetsi ea ho bula le ho koala ea likete tse leshome.

9. E ka sebelisoa ho khaola le ho laola mecha ea phatlalatso.

Tšebeliso e tloaelehileng:

1. Morero oa mesebetsi ea metsi le mehloli ea metsi

2. Tšireletso ea Tikoloho

3. Meaho ea Sechaba

4. Motlakase le Litšebeletso tsa Sechaba

5. Indasteri ea kaho

6. Petroleum/ Lik'hemik'hale

7. Tšepe. Tšepe

8. Indasteri ea ho etsa pampiri

9. Lijo/Lino jj.

Litekanyo:

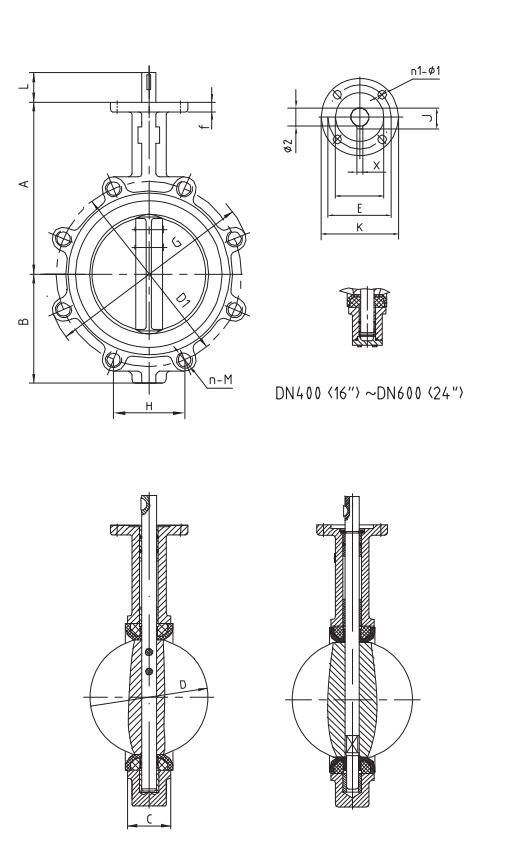

| Boholo | A | B | C | D | L | H | D1 | K | E | nM | n1-Φ1 | Φ2 | G | f | J | X | Boima ba 'mele (kg) | |

| (mm) | intshi | |||||||||||||||||

| 50 | 2 | 161 | 80 | 43 | 53 | 28 | 88.38 | 125 | 65 | 50 | 4-M16 | 4-7 | 12.6 | 155 | 13 | 13.8 | 3 | 3.5 |

| 65 | 2.5 | 175 | 89 | 46 | 64 | 28 | 102.54 | 145 | 65 | 50 | 4-M16 | 4-7 | 12.6 | 179 | 13 | 13.8 | 3 | 4.6 |

| 80 | 3 | 181 | 95 | 46 | 79 | 28 | 61.23 | 160 | 65 | 50 | 8-M16 | 4-7 | 12.6 | 190 | 13 | 13.8 | 3 | 5.6 |

| 100 | 4 | 200 | 114 | 52 | 104 | 28 | 68.88 | 180 | 90 | 70 | 8-M16 | 4-10 | 15.77 | 220 | 13 | 17.8 | 5 | 7.6 |

| 125 | 5 | 213 | 127 | 56 | 123 | 28 | 80.36 | 210 | 90 | 70 | 8-M16 | 4-10 | 18.92 | 254 | 13 | 20.9 | 5 | 10.4 |

| 150 | 6 | 226 | 139 | 56 | 156 | 28 | 91.84 | 240 | 90 | 70 | 8-M20 | 4-10 | 18.92 | 285 | 13 | 20.9 | 5 | 12.2 |

| 200 | 8 | 260 | 175 | 60 | 202 | 38 | 112.89/76.35 | 295 | 125 | 102 | 8-M20/12-M20 | 4-12 | 22.1 | 339 | 15 | 24.1 | 5 | 19.7 |

| 250 | 10 | 292 | 203 | 68 | 250 | 38 | 90.59/91.88 | 350/355 | 125 | 102 | 12-M20/12-M24 | 4-12 | 28.45 | 406 | 15 | 31.5 | 8 | 31.4 |

| 300 | 12 | 337 | 242 | 78 | 302 | 38 | 103.52/106.12 | 400/410 | 125 | 102 | 12-M20/12-M24 | 4-12 | 31.6 | 477 | 20 | 34.6 | 8 | 50 |

| 350 | 14 | 368 | 267 | 78 | 333 | 45 | 89.74/91.69 | 460/470 | 125 | 102 | 16-M20/16-M24 | 4-14 | 31.6 | 515 | 20 | 34.6 | 8 | 71 |

| 400 | 16 | 400 | 325 | 102 | 390 | 51/60 | 100.48/102.42 | 515/525 | 175 | 140 | 16-M24/16-M27 | 4-18 | 33.15 | 579 | 22 | 36.15 | 10 | 98 |

| 450 | 18 | 422 | 345 | 114 | 441 | 51/60 | 88.38/91.51 | 565/585 | 175 | 140 | 20-M24/20-M27 | 4-18 | 37.95 | 627 | 22 | 40.95 | 10 | 125 |

| 500 | 20 | 480 | 378 | 127 | 492 | 57/75 | 96.99/101.68 | 620/650 | 210 | 165 | 20-M24/20-M30 | 4-18 | 41.12 | 696 | 22 | 44.15 | 10 | 171 |

| 600 | 24 | 562 | 475 | 154 | 593 | 70/75 | 113.42/120.45 | 725/770 | 210 | 165 | 20-M27/20-M33 | 4-22 | 50.65 |

| 22 | 54.65 | 16 | 251 |

Kgwebo ya rona e ikemiseditse ho sebetsa ka botshepehi, ho sebeletsa bareki bohle ba rona, le ho sebetsa theknolojing e ntjha le mochining o motjha ka ho tswela pele bakeng sa Ditheko tsa Theko e Ntle tsa ho lwantsha mollo ka ductile stem iron stem lug butterfly valve e nang le kgokelo ya Wafer, Boleng bo botle, ditshebeletso tse nakong le theko e matla, kaofela di re hapile botumo bo botle tshimong ya xxx ho sa tsotelehe tlholisano e matla ya matjhaba.

Litheko tsaLi-valve tsa Chaena le Li-valve tsa Serurubele, Ka lihlahisoa tse ngata tsa Chaena lefatšeng ka bophara, khoebo ea rona ea machabeng e ntse e hola ka potlako 'me matšoao a moruo a eketseha haholo selemo le selemo. Re na le kholiseho e lekaneng ea ho u fa lihlahisoa le tšebeletso e betere, hobane re matla le ho feta, re litsebi ebile re na le boiphihlelo malapeng le machabeng.