1. Tlhahlobo ea sebopeho

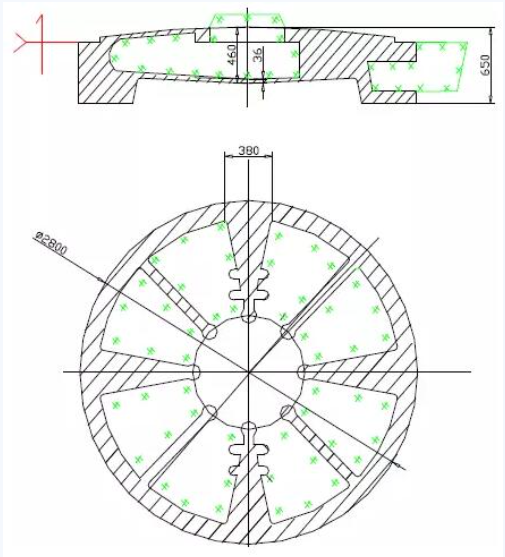

(1) Senavalafo ea serurubelee na le sebopeho se chitja se bōpehileng joaloka kuku, lesoba le ka hare le hokahantsoe le ho tšehetsoa ke likhopo tse 8 tse matlafatsang, lesoba le ka holimo la Φ620 le buisana le lesoba le ka hare, le karolo e setseng eavalafoha e koetsoe, karolo e ka hare ea lehlabathe e thata ho e lokisa 'me e bonolo ho e fetola. Mosi o ntšang metsi le ho hloekisa lesoba le ka hare ho tlisa mathata a maholo, joalo ka ha ho bontšitsoe ho Setšoantšo sa 1.

Botenya ba lebota la di-castings bo fapana haholo, botenya bo boholo ba lebota bo fihla ho 380mm, mme botenya bo bonyane ba lebota ke 36mm feela. Ha ho betla ho tiile, phapang ya mocheso e kgolo, mme ho fokotseha ho sa lekanang ho ka hlahisa dikoti tse fokotsehang le diphoso tsa ho fokotseha ha mathoko, e leng se tla baka ho dutla ha metsi tekong ya hydraulic.

2. Moralo oa ts'ebetso:

(1) Sebaka se arohaneng se bontshitswe ho Setshwantsho sa 1. Beha pheletso e nang le masoba lebokoseng le ka hodimo, etsa motheo o felletseng wa lehlabathe ka hara mokoti o bohareng, mme o lelefatse hlooho ya motheo ka nepo ho nolofatsa ho tiisetswa ha motheo wa lehlabathe le motsamao wa motheo wa lehlabathe ha lebokose le phetlwa. E tsitsitse, bolelele ba hlooho ya motheo ya cantilever ya masoba a mabedi a foufetseng ka lehlakoreng bo bolelele ho feta bolelele ba lesoba, e le hore setsi sa matla a khoheli sa motheo oohle wa lehlabathe se sekamele lehlakoreng la hlooho ya motheo ho netefatsa hore motheo wa lehlabathe o tsitsitse ebile o tsitsitse.

Sistimi ea ho tšela e koetsoeng hanyane ea amoheloa, ∑F kahare: ∑F e otlolohileng: ∑F e otlolohileng=1:1.5:1.3, sprue e sebelisa tube ea ceramic e nang le bophara ba ka hare ba Φ120, 'me likotoana tse peli tsa litene tse hanyetsang tsa 200×100×40mm li beoa tlase ho thibela tšepe e qhibilihisitsoeng ho tsoa ka kotloloho. Bakeng sa hlobo ea lehlabathe le nang le tšusumetso, sefe ea ceramic ea foam ea 150×150×40 e kentsoe tlase ho sepeiti, 'me lipeipi tse 12 tsa ceramic tse nang le bophara ba ka hare ba Φ30 li sebelisoa bakeng sa sepeiti sa ka hare ho hokela ka ho lekana tlase ho lahla ka tankeng ea pokello ea metsi tlase ho sepeiti ho etsa moralo oa ho tšela o tlase, joalo ka ha ho bontšitsoe ho Setšoantšo sa 2 Essence

(3) Beha masoba a moea a 14 ∮20 a nang le dikoti hloboleng e ka hodimo, beha lesoba la mothapo wa lehlabathe wa Φ200 bohareng ba hlooho ya motheo, beha tshepe e batang dikarolong tse teteaneng le tse kgolo ho netefatsa ho tiya ha ho betlwa ka ho leka-lekana, mme o sebedise molaomotheo wa katoloso ya graphitization ho hlakola Sehatsetsi sa ho fepa se sebediswa ho ntlafatsa chai ya tshebetso. Boholo ba lebokose la lehlabathe ke 3600×3600×1000/600mm, mme se tjheselleditswe ka poleiti ya tshepe e teteaneng ya 25mm ho netefatsa matla a lekaneng le ho tiya, jwalo ka ha ho bontshitswe ho Setšoantšo sa 3.

3. Taolo ea ts'ebetso

(1) Ho etsa mohlala: Pele o etsa mohlala, sebedisa sampole e tloaelehileng ya Φ50×50mm ho leka matla a ho hatella a lehlabathe la resin ≥ 3.5MPa, mme o tiise tshepe e batang le sehatsetsi ho netefatsa hore hlobo ya lehlabathe e na le matla a lekaneng ho thibela graphite e hlahiswang ha tshepe e qhibilihisitsweng e tiisa katoloso ya dikhemikhale, le ho thibela tshepe e qhibilihisitsweng ho ama karolo ya sehatsetsi nako e telele ho baka ho hlatsuwa ha lehlabathe.

Ho etsa motheo: Motheo wa lehlabathe o arotsoe ka dikarolo tse 8 tse lekanang ka dikgopo tse 8 tse matlafatsang, tse hokahantsweng ka hara mokoti o bohareng. Ha ho na dikarolo tse ding tse tshehetsang le tsa ho ntsha mosi ntle le hlooho ya bohareng ba motheo. Haeba motheo wa lehlabathe o sa kgone ho lokiswa mme Mosi, ho falla ha motheo wa lehlabathe le masoba a moya ho tla hlaha kamora ho tshelwa. Hobane sebaka sohle sa motheo wa lehlabathe se seholo, se arotsoe ka dikarolo tse robedi. Se tlameha ho ba le matla a lekaneng le ho tiya ho netefatsa hore motheo wa lehlabathe o ke ke wa senyeha kamora ho lokollwa ha hlobo, mme o ke ke wa senyeha kamora ho tshelwa. Ho fetoha ha sebopeho, e le ho netefatsa botenya ba lebota bo tshwanang ba ho lahla. Ka lebaka lena, re entse lesapo le ikgethang la motheo ka ho kgetheha, mme ra le tlama lesapong la motheo ka thapo ya moya ho hula kgase ya ho ntsha mosi hloohong ya mantlha ho netefatsa hore hlobo ya lehlabathe e tiile ha ho etswa motheo. Jwalo ka ha ho bontshitswe ho Setšoantšo sa 4.

(4) Lebokose le kwalang: Ha ho nahanoa hore ho thata ho hlwekisa lehlabathe le ka hare ho valve ya serurubele, karolo yohle ya lehlabathe e pentilwe ka dikarolo tse pedi tsa pente, karolo ya pele e pentilwe ka pente ya zirconium e thehilweng hodima joala (Baume degree 45-55), mme karolo ya pele e pentilwe mme e tjheswe. Kamora ho oma, penta karolo ya bobedi ka pente ya magnesium e thehilweng hodima joala (Baume degree 35-45) ho thibela ho tjheswa ho kgomarela lehlabatheng le ho tjhesa, e ke keng ya hlwekiswa. Karolo ya hlooho ya motheo e fanyehwa hodima phaephe ya tshepe ya Φ200 ya sebopeho se seholo sa lesapo la mantlha ka dikurufu tse tharo tsa M25, e tsitsitswe mme e notletswe ka lebokose la lehlabathe la hlobo le ka hodimo le nang le dikgurufu tsa dikurufu mme e hlahlojwe hore na botenya ba lebota la karolo ka nngwe bo lekana.

4. Mokhoa oa ho qhibilihisa le ho tšolla

(1) Sebelisa tšepe ea kolobe ea boleng bo holimo ea Benxi low-P, S, Ti Q14/16#, 'me u e kenye ka karolelano ea 40% ~ 60%; likarolo tse nyenyane tse kang P, S, Ti, Cr, Pb, jj. li laoloa ka thata ka tšepe e senyehileng, 'me ha ho mafome le oli tse lumelloang, karolelano ea ho eketsa ke 25% ~ 40%; tefiso e khutlisitsoeng e tlameha ho hloekisoa ka ho thunya ka lithunya pele e sebelisoa ho netefatsa bohloeki ba tefiso.

(2) Taolo ea karolo e ka sehloohong kamora setofo: C: 3.5-3.65%, Si: 2.2%-2.45%, Mn: 0.25%-0.35%, P≤0.05%, S: ≤0.01%, Mg (masala): 0.035% ~0.05%, tlas'a motheo oa ho netefatsa spheroidization, moeli o tlase oa Mg (masala) o lokela ho nkoa ka hohle kamoo ho ka khonehang.

(3) Kalafo ea ho enta ka spheroidization: ho sebelisoa li-spheroidizer tse nang le magnesium e tlase le tse sa tloaelehang haholo, 'me karolelano ea ho eketsa ke 1.0% ~ 1.2%. Mokhoa o tloaelehileng oa ho ntša metsi ka spheroidization, 0.15% ea ente ea hang e koahetsoe holim'a nodulizer e ka tlase ho sephutheloana, 'me spheroidization e phethetsoe. Ebe slag e fokotsoa bakeng sa ente ea bobeli ea 0.35%, 'me ente ea phallo ea 0.15% e etsoa nakong ea ho tšela.

(5) Ho amohelwa mokhoa oa ho tšela ka potlako mochesong o tlase, mocheso oa ho tšela ke 1320°C~1340°C, 'me nako ea ho tšela ke 70~80s. Tšepe e qhibilihisitsoeng e ke ke ea sitisoa nakong ea ho tšela, 'me kopi ea sprue e lula e tletse ho thibela khase le lintho tse kenyellelitsoeng ho kenella hlobo ka har'a sekoti.

5. Liphetho tsa liteko tsa ho lahla

(1) Leka matla a ho thapolla a boloko ba teko bo entsweng ka foreime: 485MPa, ho lelefatsa: 15%, ho thatafala ha Brinell HB187.

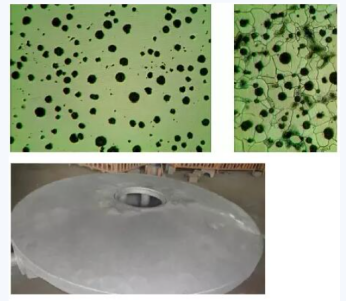

(2) Sekhahla sa spheroidization ke 95%, boholo ba graphite ke sehlopha sa 6, mme pearlite ke 35%. Sebopeho sa metallographic se bontshitswe ho Setšoantšo sa 5.

(3) Ha ho na diphoso tse ka rekotwang tse fumanweng ho lemoheng diphoso tsa bobedi tsa UT le MT tsa dikarolo tsa bohlokwa.

(4) Ponahalo e bataletse ebile e boreleli (sheba Setshwantsho sa 6), ntle le diphoso tse kang ho kenyeletswa ha lehlabathe, ho kenyeletswa ha slag, ho kwala ha serame, jj., botenya ba lebota bo a tshwana, mme boholo bo fihlella ditlhoko tsa ditshwantsho.

(6) Teko ea khatello ea haeteroliki ea 20kg/cm2 kamora ho sebetsoa ha ea ka ea bontša ho lutla ho hong.

6. Qetello

Ho ya ka dibopeho tsa sebopeho sa valve ena ya serurubele, bothata ba ho fetoha ho sa tsitsang le ho bonolo ha karolo e kgolo ya lehlabathe bohareng le tlhoekiso e thata ya lehlabathe bo rarollwa ka ho hatisa moralo wa moralo wa tshebetso, tlhahiso le ho lokisa karolo e kgolo ya lehlabathe le tshebediso ya dikoahelo tse thehilweng ho zirconium. Ho bewa ha masoba a moya ho qoba monyetla wa masoba a di-castings. Ho tloha tsamaisong ya taolo ya tjhaja ya ontong le ya runner, skrine ya sefe ya foam ceramic le theknoloji ya ceramic ingate di sebediswa ho netefatsa bohlweki ba tshepe e qhibilihisitsweng. Kamora kalafo e mengata ya ente, sebopeho sa metallographic sa di-castings le tshebetso e fapaneng e felletseng e fihletse ditlhoko tse tloaelehileng tsa bareki

Ho tloha hoTianjin Tanggu Water-seal valve Co., Ltd. Valve ea serurubele, valve ea heke, Sesefa sa Y, valve ea tlhahlobo ea poleiti e habeli ea wafertlhahiso.

Nako ea poso: Mmesa-29-2023