Sebopeho sa bokaholimo ba khokahano ea valve se ama ka kotloloho ts'ebetso ea ho koala valve, mokhoa oa ho kenya le ts'epo tsamaisong ea liphaephe.TWSka bokhutšoanyane ke tla hlahisa mefuta e meholo ea khokahano le litšobotsi tsa eona sehloohong sena.

Mokhoa oa ho hokahanya oa bokahohle o finyella ho koala ka ho tiisa ka libolte tsa li-flange tse kopantsoeng.

Mefuta e tloaelehileng ea ho tiisa bokaholimo:

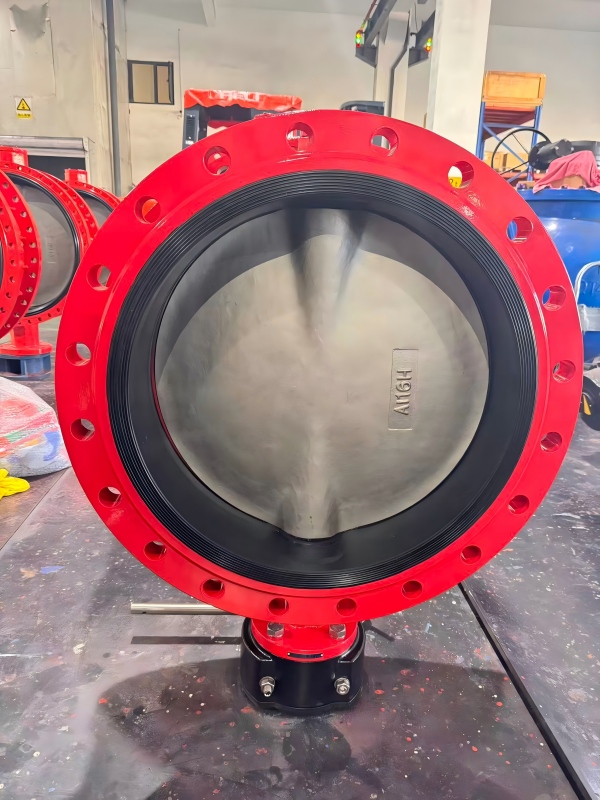

-Bokaholimo bo hlahelletseng: Moralo o tloaelehileng haholo, o nang le bokaholimo bo koalang bo hlahelletseng ba 2-3mm, bo loketseng sebaka se seholo sa khatello (PN10-PN25).

-Bokaholimo bo kobehileng le bo kobehileng: tshebetso e betere ya ho kwala, e loketse metswedi e tukang le e chefo.

-Bokaholimo ba mokoti: ho koala ho molemo ka ho fetisisa, ho sebelisoa bakeng sa mecha ea phatlalatso e kotsi haholo le maemo a khatello e phahameng.

-Bokaholimo ba khokahano ea lesale: Gasket ea lesale la tšepe, e etselitsoeng lits'ebetso tsa khatello e phahameng le mocheso o phahameng. Melemo: Ho koala ho tšepahalang le ho qhaqhoa habonolo.

Mathata: bophahamo bo boholo le boima, litšenyehelo tse phahameng.

Valve e na le moralo o sa kobehang, o tiisitsoeng ka liboutu tse telele pakeng tsa li-flange tsa liphaephe. Litšobotsi tsa bohlokoa li kenyelletsa sebopeho se senyenyane, kaho e bobebe, le katleho ea litšenyehelo. Leha ho le joalo, e hloka maemo a holimo a ho kenya 'me ho thata ho e hlokomela. Moralo ona o sebelisoa haholo holi-valve tsa serurubeleleli-valve tsa ho hlahloba.

III.Likhokahano tse nang le khoele

Kgokelo e nang le khoele ke mokhoa oa khokahano oa mechini o sebelisang li-fasteners tse nang le khoele ho hokahanya likarolo 'me li ka qhaqhoa neng kapa neng.

Melemo ea ho koala: Tlhahiso e kholo e etsa hore litšenyehelo tsa tlhahiso li be tlase haholo, e leng e 'ngoe ea mekhoa ea khokahano e theko e tlaase ka ho fetisisa.

Mathata: Ho bonolo ho e lokolla tlas'a ho thothomela le moroalo oa tšusumetso, 'me khatello ea maikutlo motsong oa khoele e etsa hore matla a eona a mokhathala a be tlase.

IV. Likhokahano tsa ho tjheseletsa

Khokahano e tšepahalang ka ho fetisisa ea kamehla.

-Mofuta: Ho tjheseletsa marago: Matla a hodimo, kganyetso e tlase ya mokelikeli, e loketse maemo a thata a ho sebetsa.

-Khokelo ea ho tjheseletsa ka plug-in: Ho bonolo ho e kenya, e loketse liphaephe tse bophara bo bonyenyane. Melemo: Ha e lutle letho, ha e thothomele.

Mathata: 5. Bothata ba ho qhaqha. Mefuta e meng ea khokahano: Likhokahano tsa ho khomarela: Li sebelisoa liindastering tsa bohloeki bakeng sa ho hloekisa habonolo. Likhokahano tsa matsoho: Li sebelisoa lits'ebetsong tsa lisebelisoa le tsa hydraulic.

Lintlha tsa khetho:

1. Khetha mokhoa ho latela khatello le mocheso: khatello e phahameng le mocheso o phahameng li lokela ho kopanngoa ka welded kapa ho hokeloa ka lesale.

2. Ho ipapisitsoe le litšobotsi tsa mahareng: Bakeng sa mecha ea phatlalatso e kotsi, ho khothaletsoa ho tjheseletsa kapa libaka tse nang le manonyeletso a tenon.

3. Nahana ka ho kenya le ho hlokomela: Ho qhaqha kgafetsa kgokelo ya flange.

4. Litšenyehelo le Sebaka: Wafer e theko e tlase ebile e nyane.

V. Qetello:

Khokahano e nepahetseng ke senotlolo sa polokeho le ts'ebetso ea liphaephe. Fumana tataiso ea litsebi le litheko tsa tlholisano ho ronavalafo ea serurubele, valve ea hekeleli-valve tsa ho hlahlobaIkopanye le ronaTWSho fumana tharollo e phethahetseng bakeng sa litlhoko tsa hau.

Nako ea poso: Pulungoana-25-2025